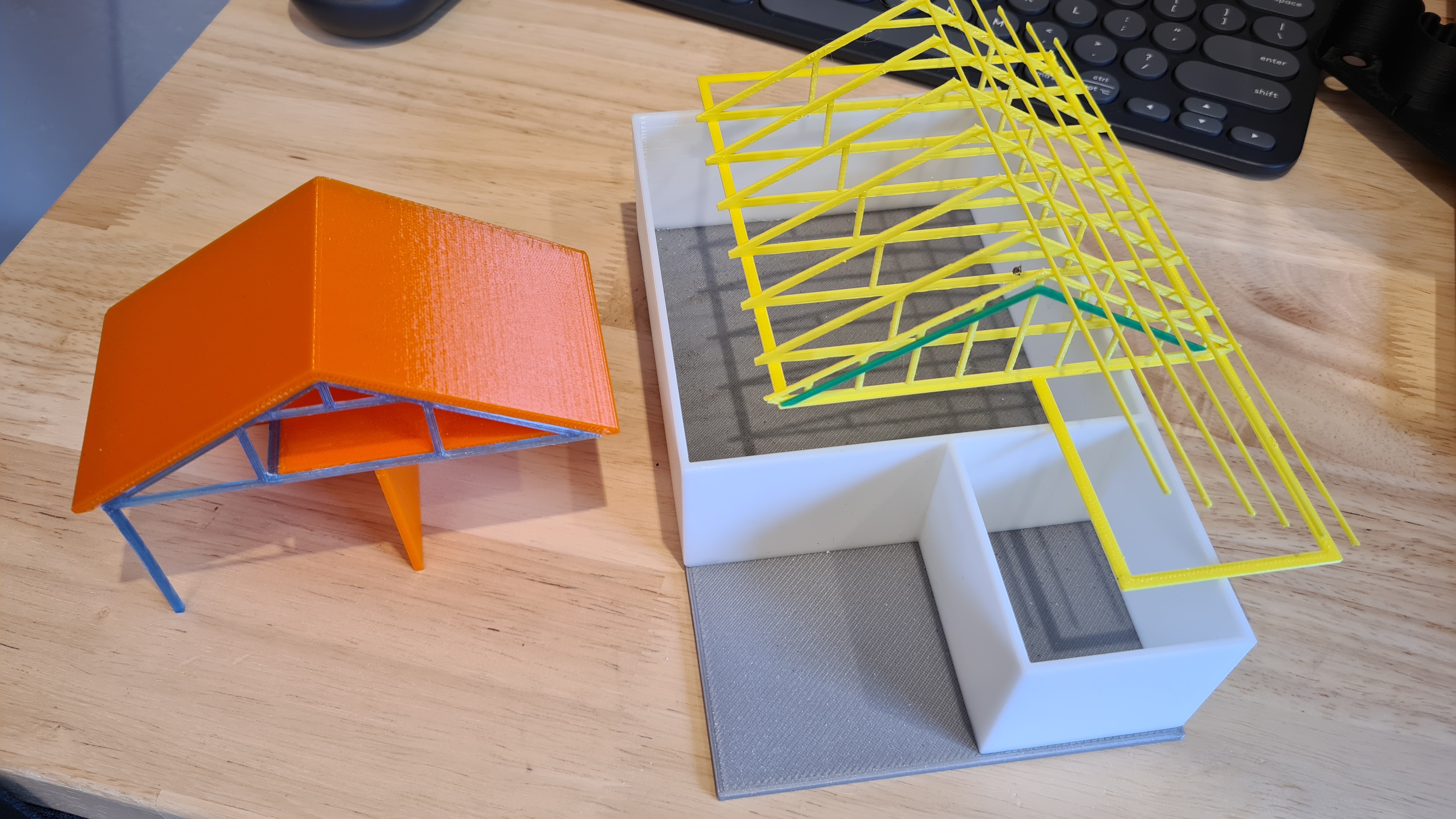

For architecture...Create precise, hands-on models that showcase your designs.  |

This garage extension model was designed to integrate Bondor SIPs, Formance SIPs, and traditional Kiwi building techniques, helping the builder visualize the full project. Now, the real structure houses many of my 3D printers. |

|

Before committing to full-scale production, visualize your concept with a detailed, functional prototype. This ladder design, for example, elegantly slides up against the wall, saving space when not in use. By creating a model first, potential design adjustments can be made early, reducing overall project costs. |

For automotive...   |

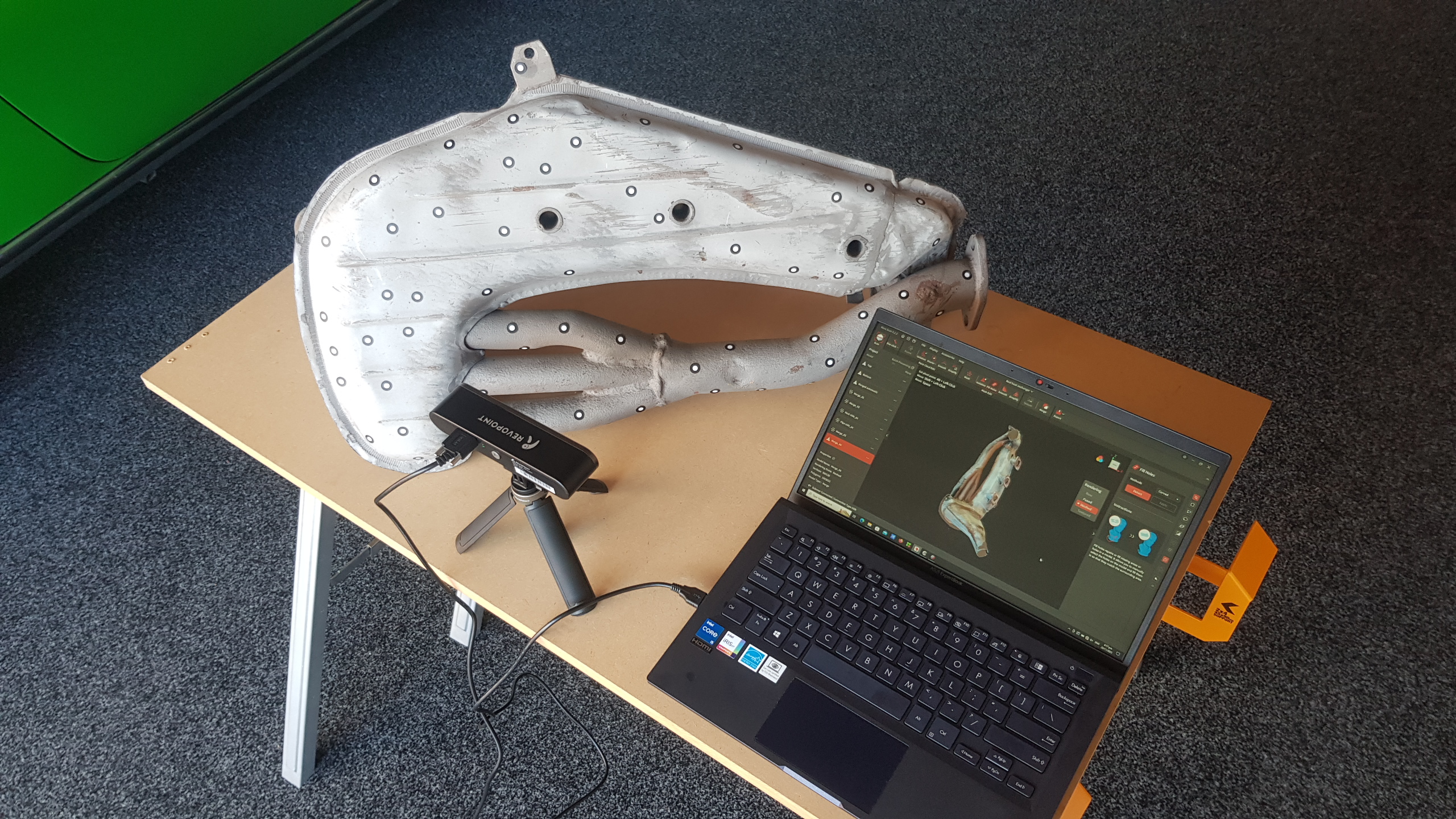

Recreate rare or missing parts with 3D scanning and printing. From Porsche engine components to custom alternator shims, I replicate parts that are otherwise irreplaceable, ensuring seamless fits for classic cars. Recreating the Unobtainable – Precision in Miniature To replace a missing, irreplaceable part from a complex Porsche 911 engine model, I used 3D scanning to capture the details of a full-sized component. This data was scaled down and reproduced in miniature, restoring the model to its original form. This process highlights the ability to replicate intricate, discontinued parts—preserving vintage designs or supporting custom automotive projects with unparalleled accuracy. |

|

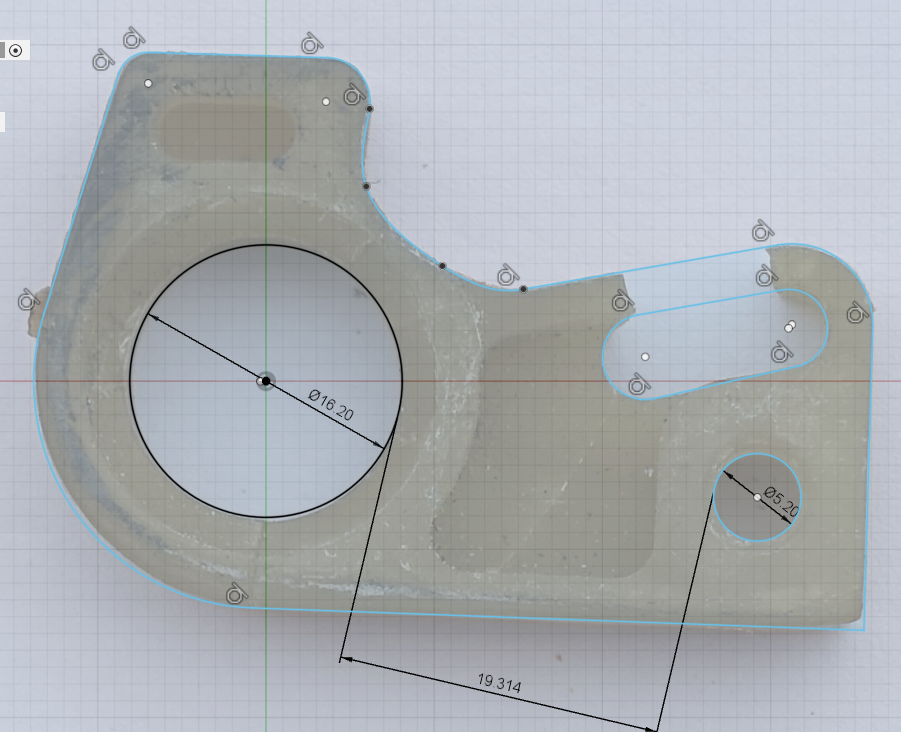

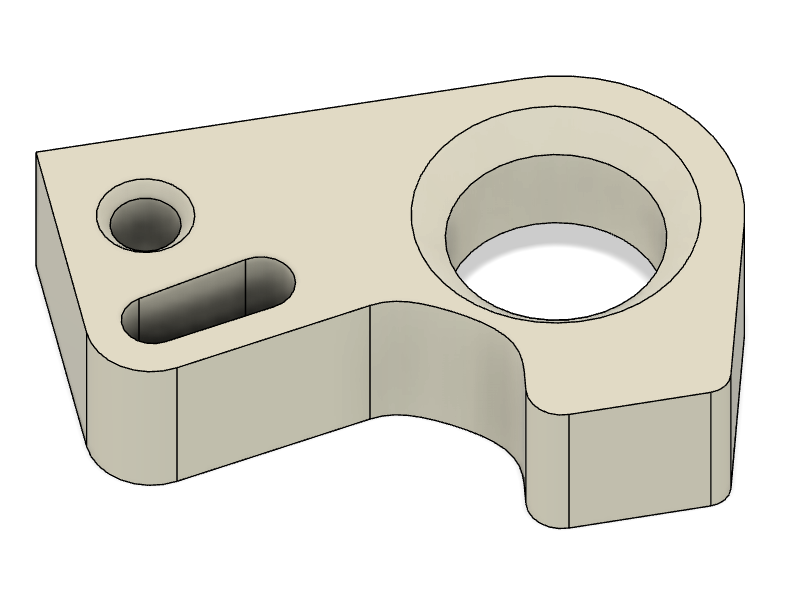

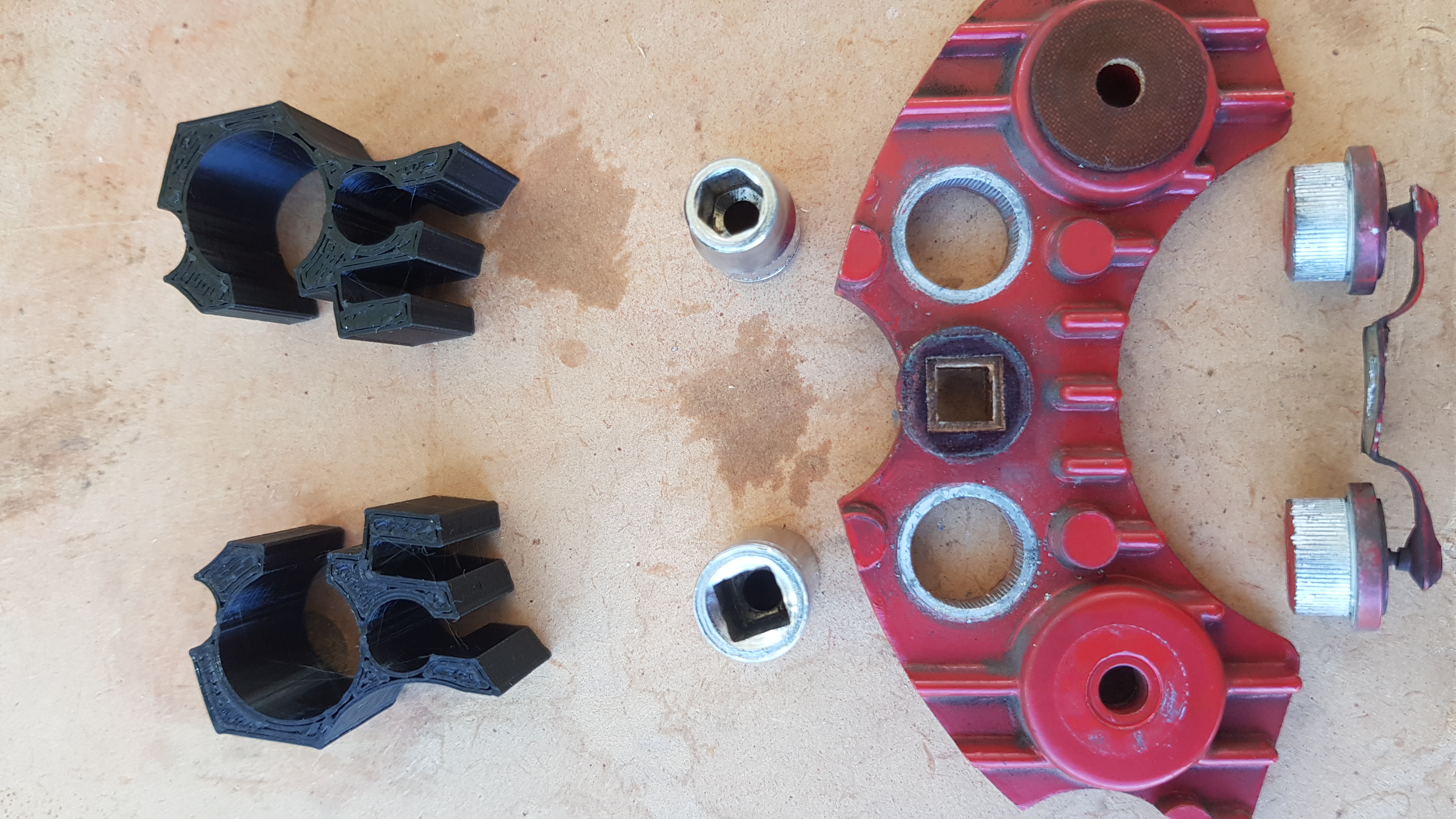

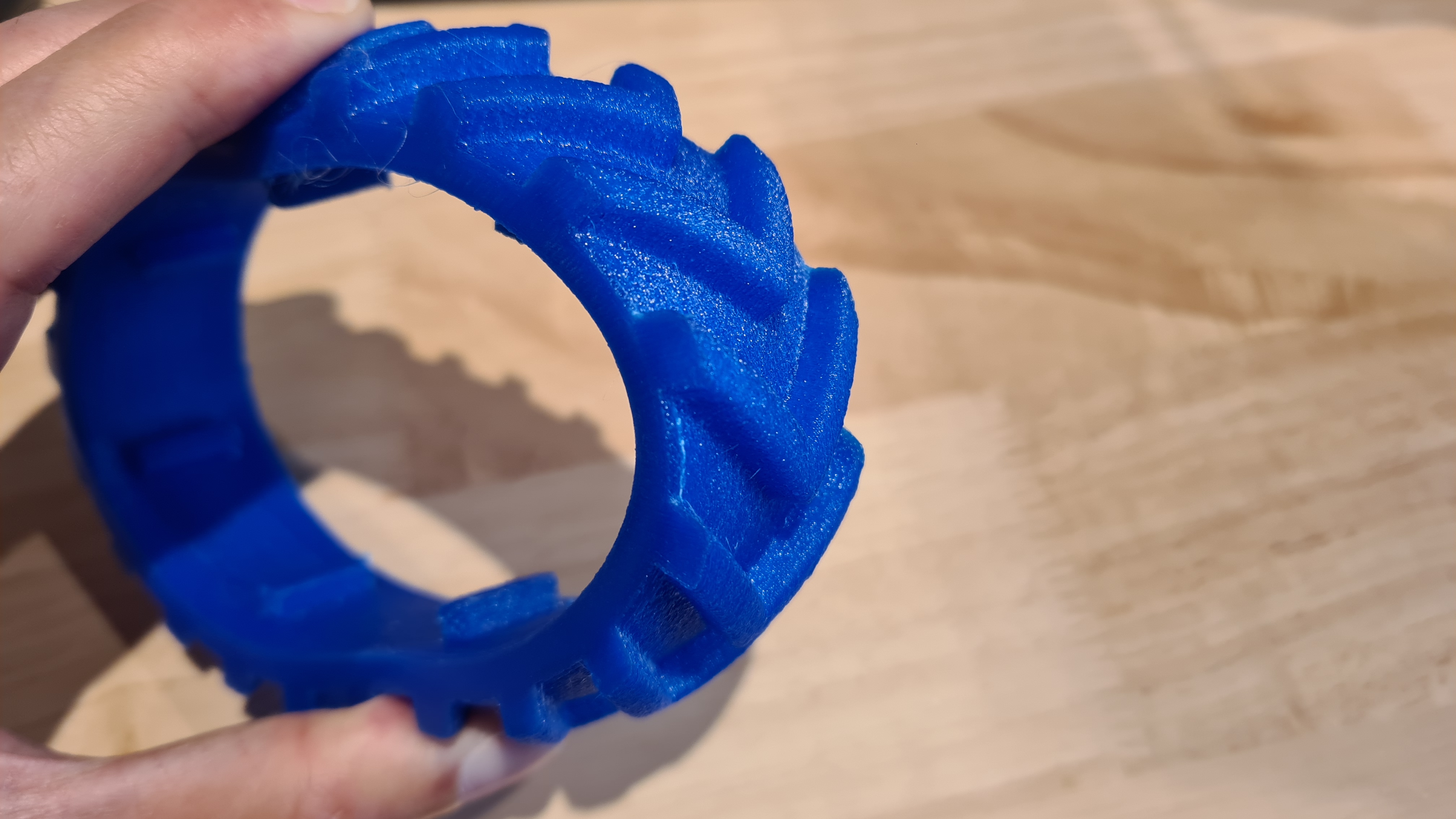

Reverse Engineering a Worn Part with Precision To replace a worn component, I began by photographing the broken original and recreating it in Fusion 360. Multiple prototypes were printed using various materials to test fit and durability. Ultimately, flexible TPU provided the best combination of resilience and performance, perfectly matching the part's function. This process highlights how custom parts can be accurately recreated and refined through iterative testing—ensuring the right material for the job without unnecessary expense. |

|

Custom Shims for Safe Alternator Repair I designed specialized shims to aid in the removal of faulty diodes from a 50-year-old alternator. The shims ensured that the press-fit components could be extracted without damaging the delicate, aged parts—offering a precise and safe solution to a challenging restoration. This project underscores the value of 3D printing in automotive restoration, where discontinued or delicate parts require custom tools for preservation and repair. |

For outdoors...Practical solutions for outdoor use are designed and printed for durability and performance.  |

I design and print practical outdoor components built to withstand the elements. From UV-resistant chicken coop vents to rain barrel filters, each part is crafted with durability in mind. A custom bracket for securing a roost bar was also designed, ensuring stability and ease of installation inside the coop. |

|

|

These solutions enhance outdoor structures by incorporating weather-resistant materials and functional designs, providing long-lasting, practical fixes that aren’t readily available off the shelf. |

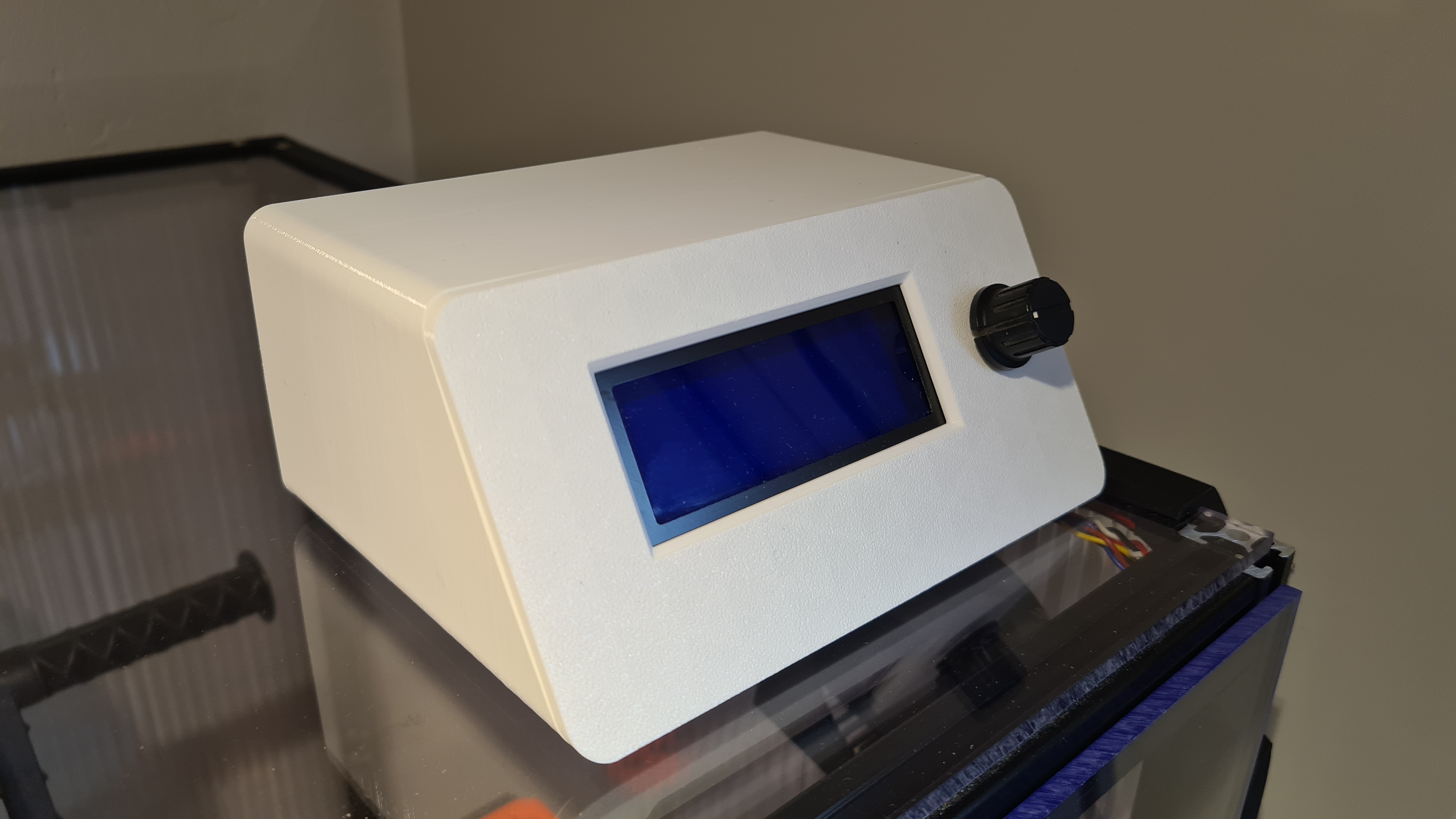

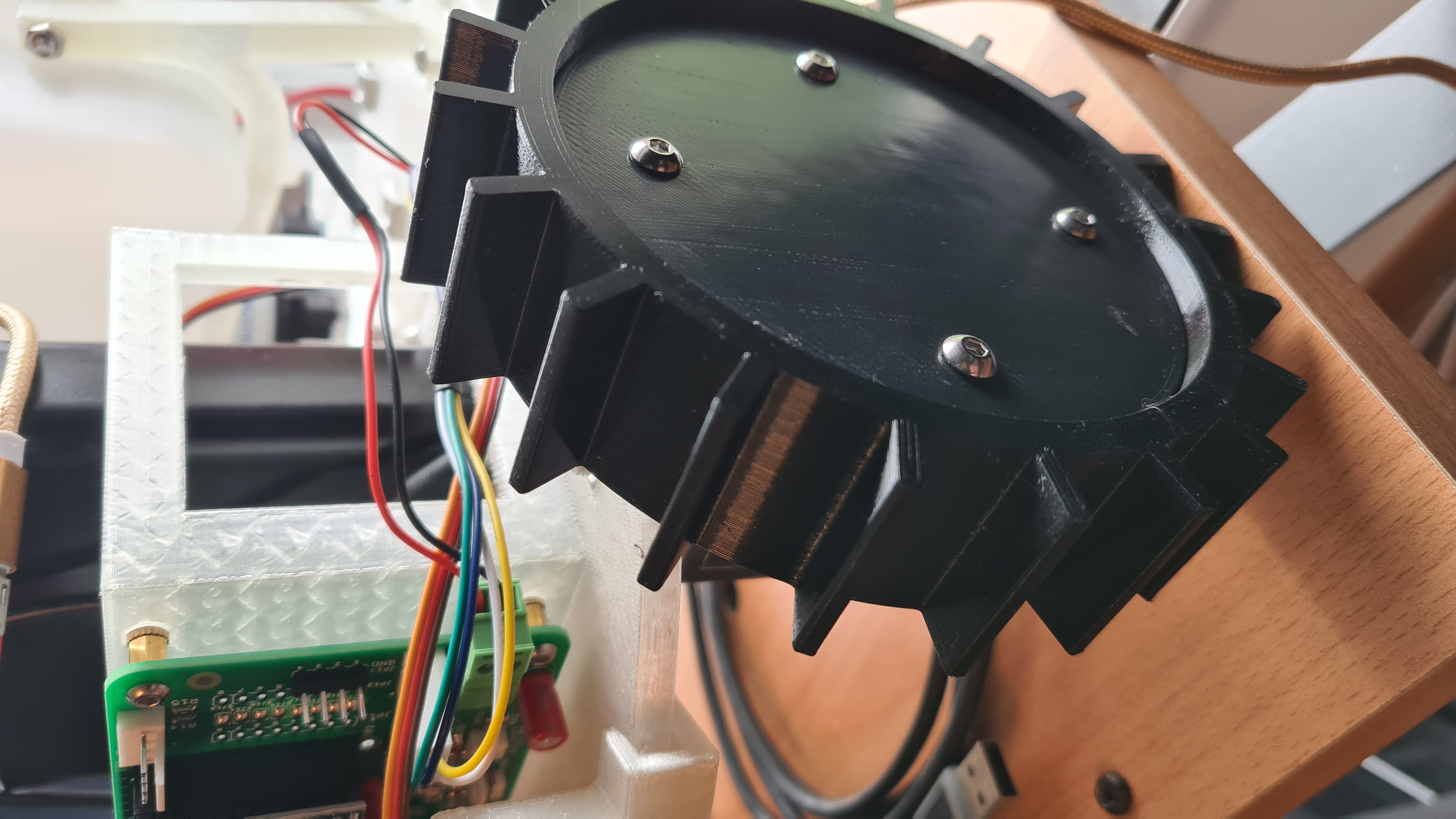

For electronics...Custom enclosures and robot wheels made to fit. Precision-printed to protect and enhance your electronic projects.    |

Other... |

Unique, Custom-Made Solutions From intricate components to one-of-a-kind gadgets, I design and print parts that simply can’t be bought off the shelf. Whether it's a specialized tool, replacement piece, or a custom design, 3D printing makes the impossible possible—tailored exactly to your needs. |

Copyright 2025

Martin van den Nieuwelaar

Last updated 3 Jan 2025